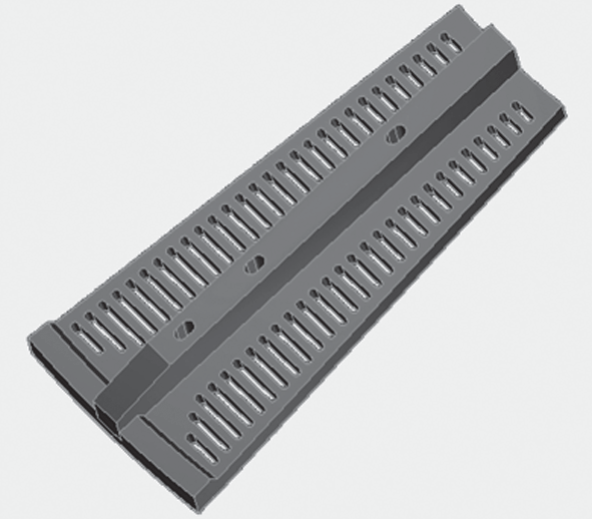

PEW400×600 Jaw Plates

When it comes to PEW400×600 jaw plates, Qiming Casting had manufactured those wear parts for Canadian customers. When you need replacement jaws for crushing equipment with minimal downtime, count on Qiming Casting. We carry replacement jaw castings for most crushing equipment, or we can custom manufacture replacement jaws to your specifications within one week of…

Download Brochure

Download Brochure Product List

Product List