Quality Assurance Reports

Qiming Casting supplies complete quality assurance reports for customers. Those quality assurance reports include:

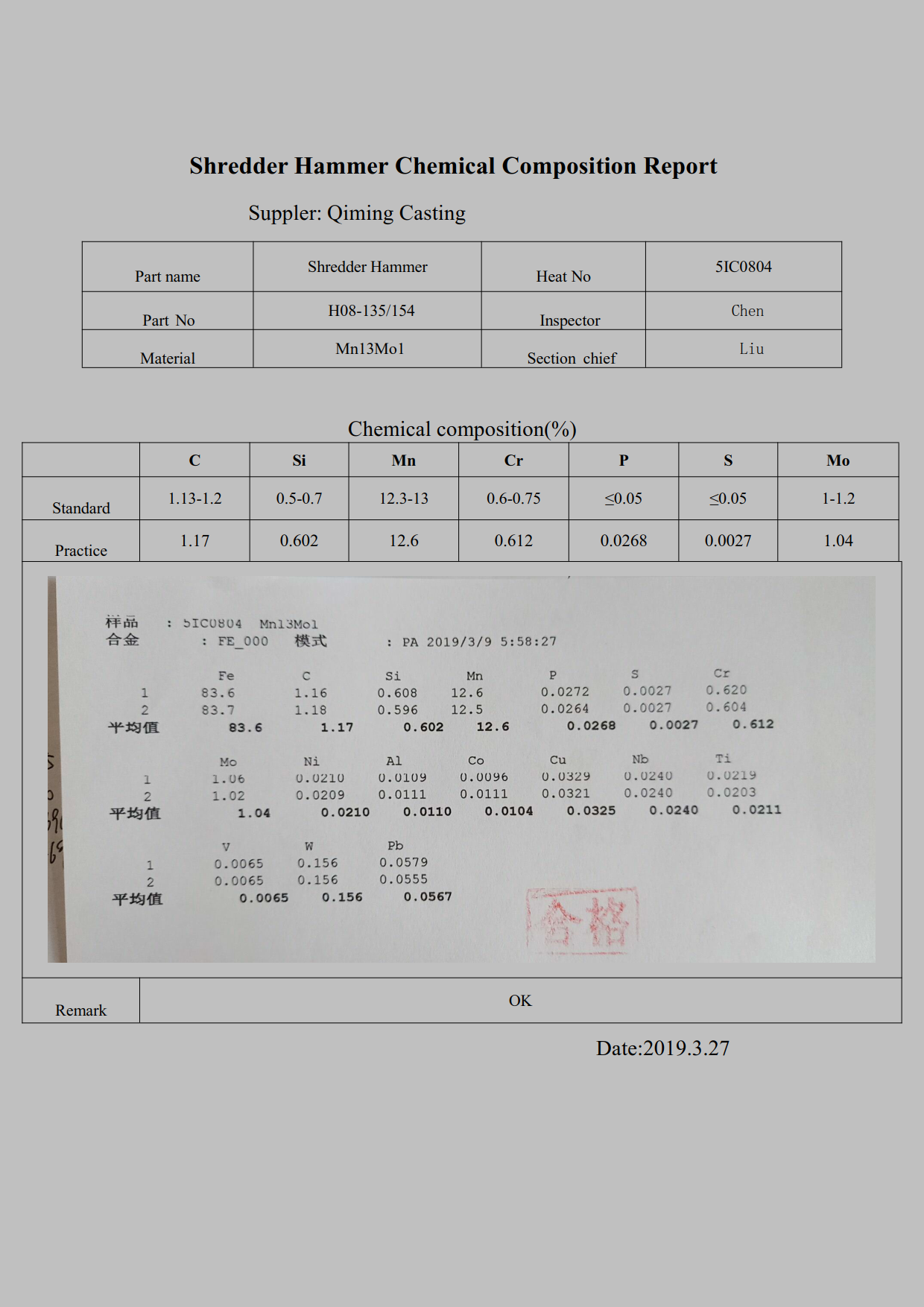

- Chemical Composition Report

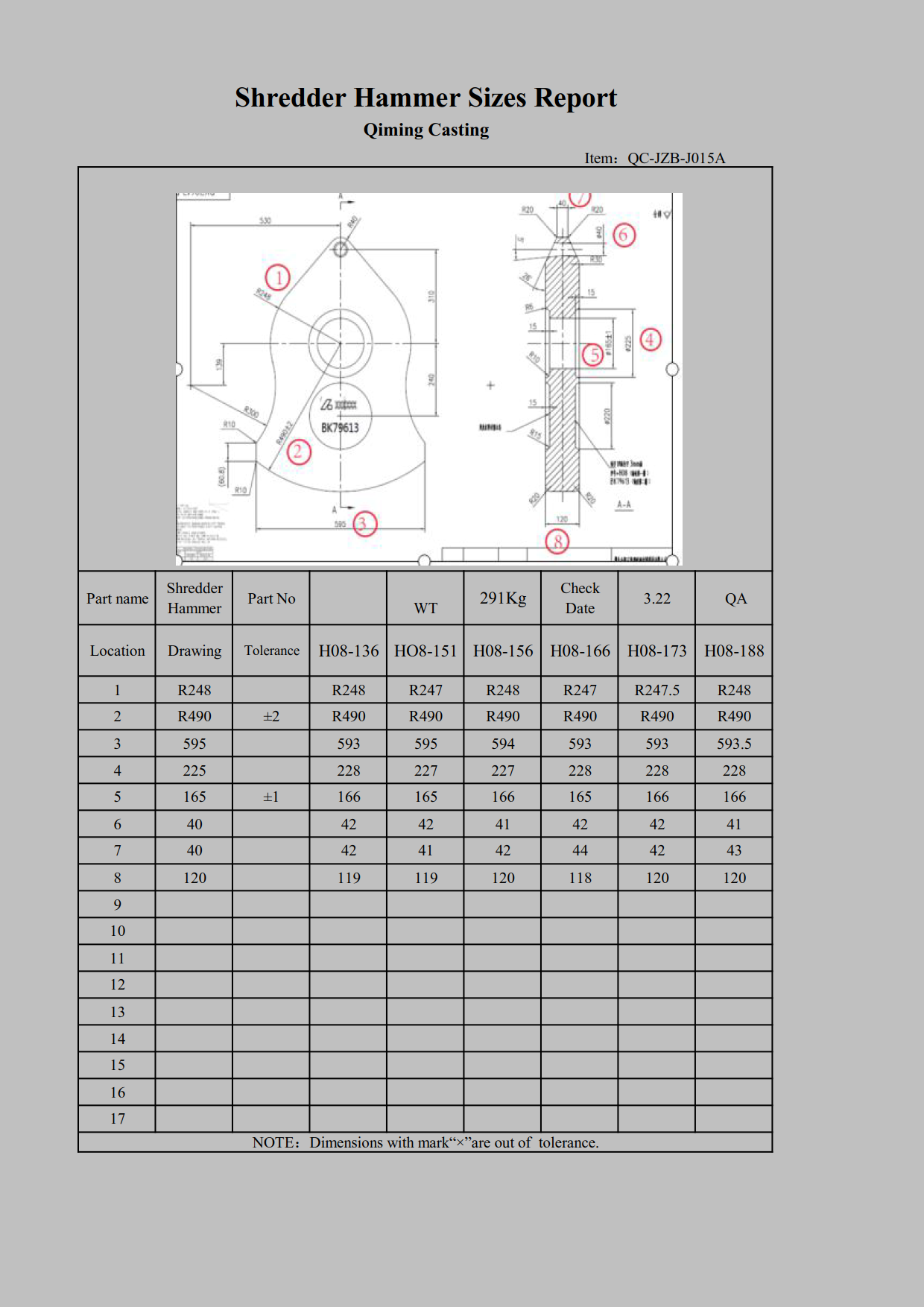

- Size Report

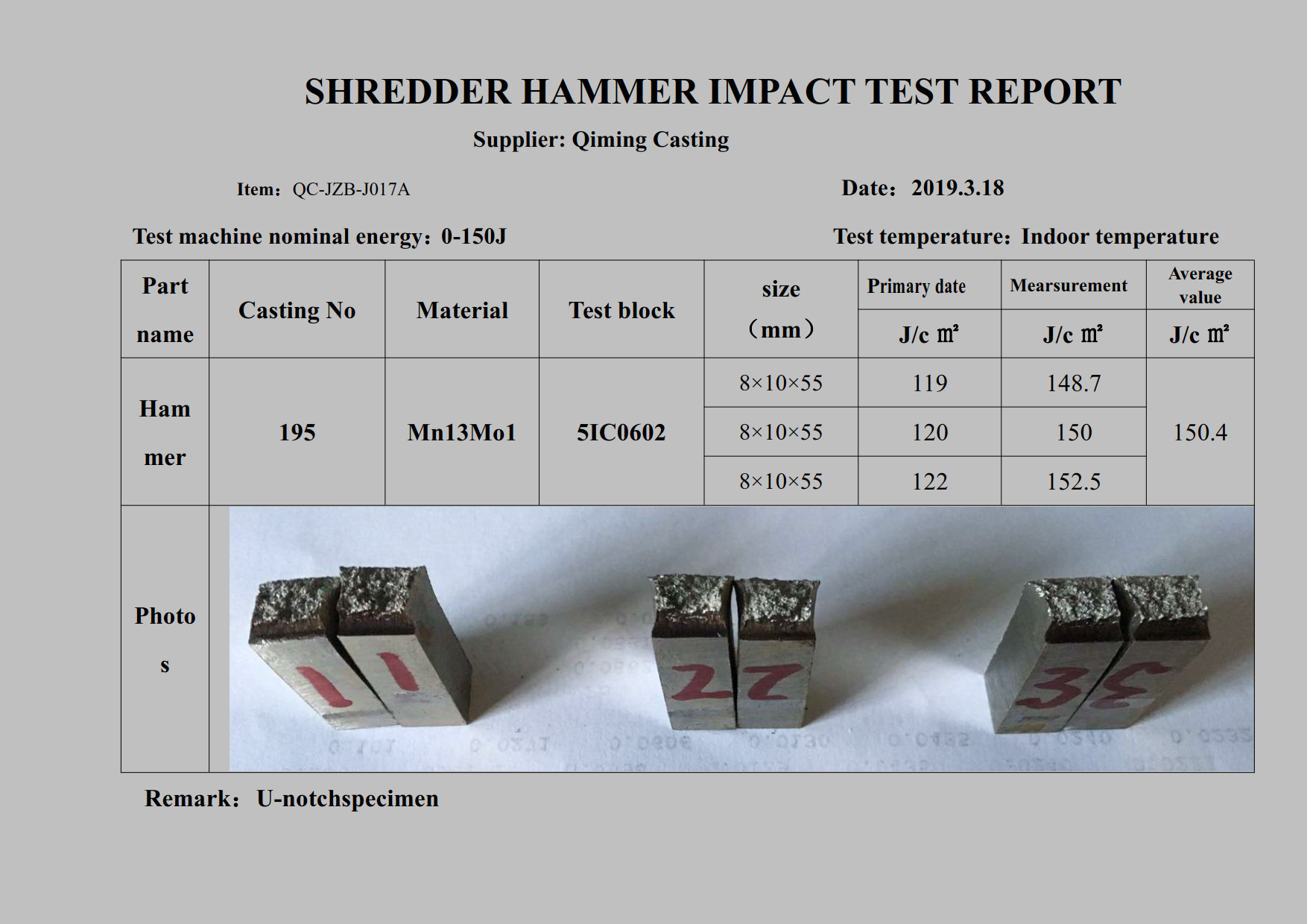

- Impact Test Report

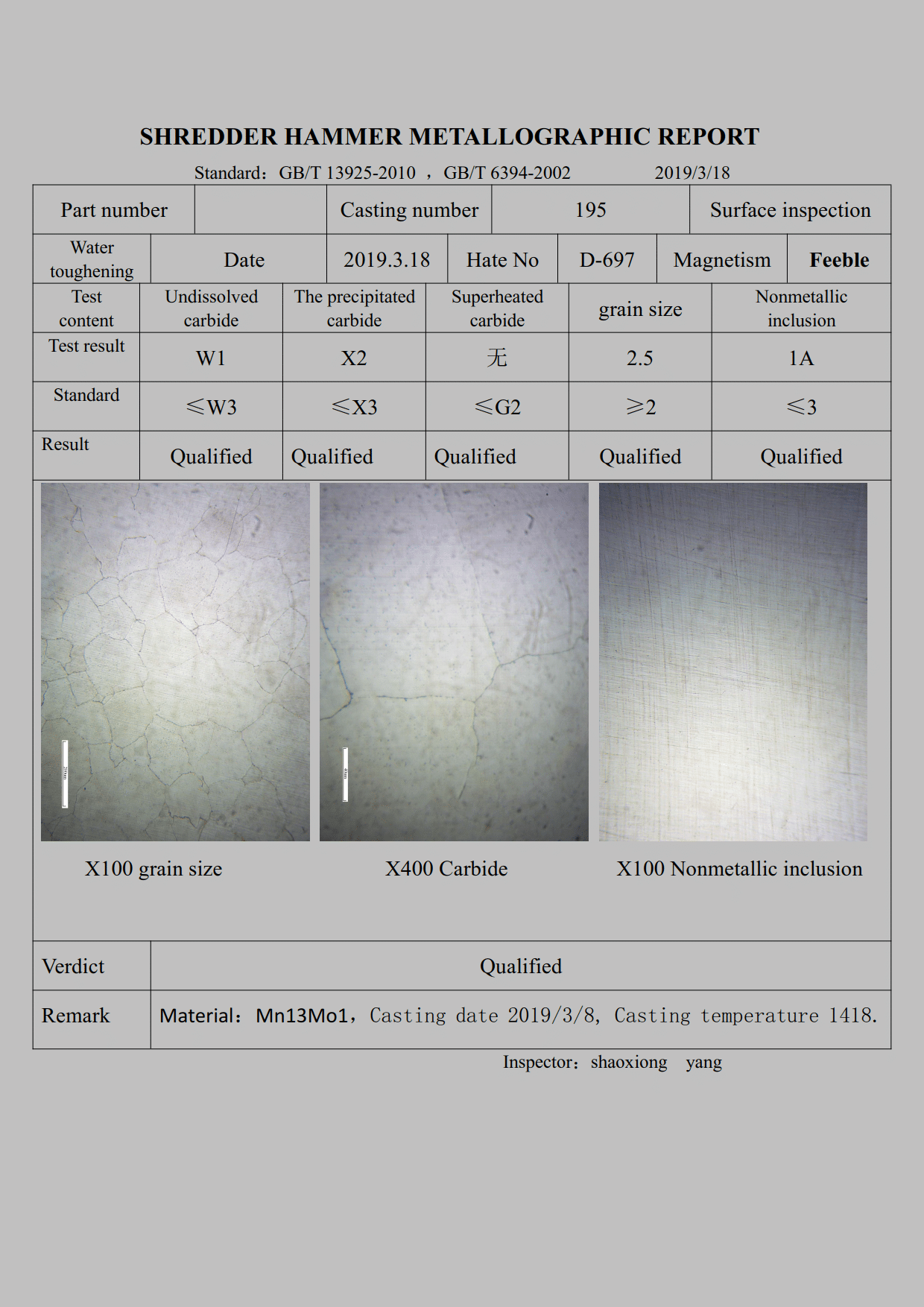

- Metallographic Report

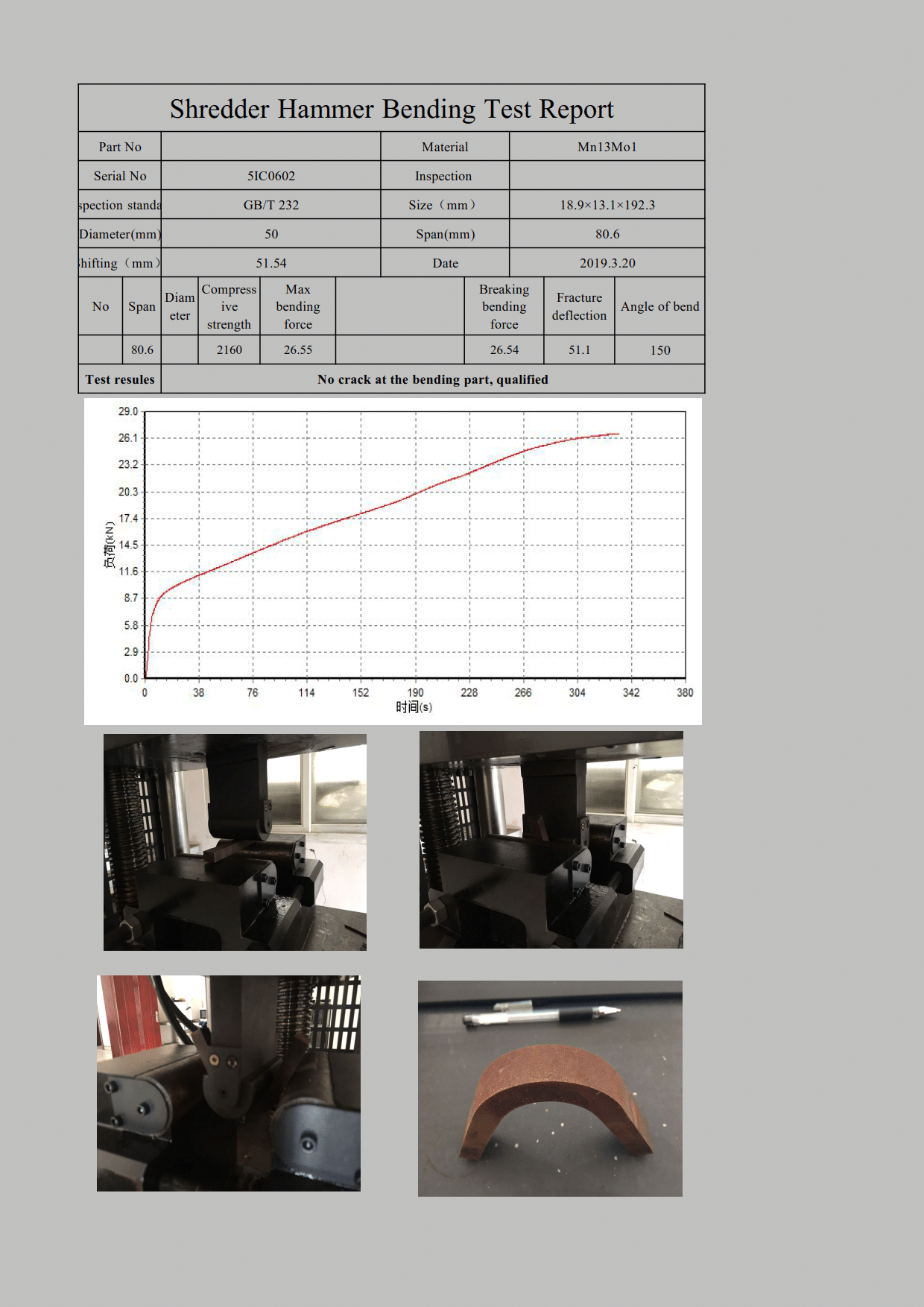

- Bending Test Report

- Other Reports

Download Brochure

Download Brochure Product List

Product List