Cone Crusher Liner Selection

Cone crusher liner selection, is a very important selection for users. Cone crusher liners need periodic replacement to protect the cone crusher and keep the output, so the better selection, the less cost, and more profit. In this post, we will discuss material selection, cavity selection, and foundry selection.

1. Material selection:

High manganese which has strong resistance, high pressure and wear resistant,so it becomes the best choice, having work hardening characteristics unmatched compare with other wear-resistant materials.Because when the surface get large impact load or large contact stress, the steel surface will layer hardened, HB200 to HB500 by rapid increases , at the same time, the inner layer of austenitic steel still maintain good toughness.

The main feature of high manganese steel:

- The greater the impact of external load, its higher surface abrasion resistance;

- With the gradual wear of the surface-hardened layer, a new hardening layer is continuously formed.

- The special properties of high manganese steel, suitable for the production of wear-resistant member is subjected to prolonged wear for a long time widely used in metallurgy, mining, building materials, railway, electricity, coal and other mechanical devices.

The manganese trademark : Mn13CrMo, Mn18Cr2Mo, Mn13Cr2Mo

Cone crusher liner selection chemical elements from Qiming Casting Test Report.

From the test report, Mn13 is the high manganese steel and Mn18 is Ultra-high manganese steel, The content of elements “Si” can effect the Impact toughness , need less than 0.5%,the lower content of element “P” and “S” are the basic,”Cr” can improve the wear,but need less than 2%, The “Mo” can improve toughness.

In a word, the final cone liner material selection based on the type of crush ,quality and cost control.

2. Cone crusher liner cavity selection:

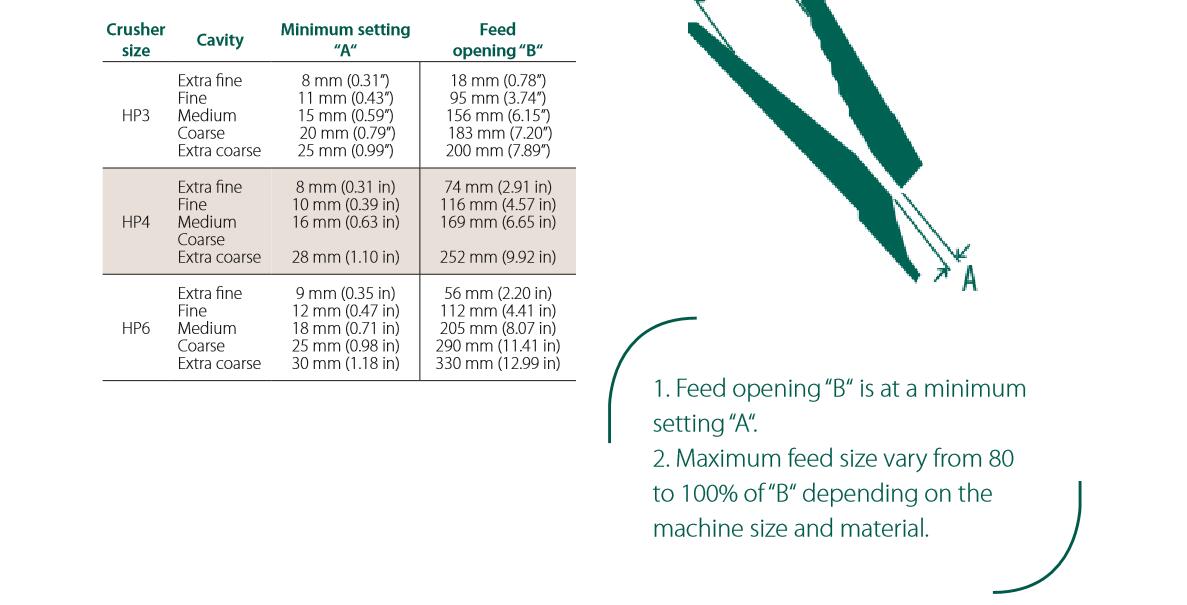

Cone crushers have several cavity options with different feed openings and setting ranges. The correct cavity can be selected based on the feed size and setting.

For example HP Series cone crusher, 5 types of cavity:

Cavity type: EC,C,M,EF,F

Cavity selection based on feed opening:

3. Foundry selection:

Choose a good foundry very help you to get more profit and better service. In fact, 80% crusher manufactures are not casting foundry, they are Assembly and design plants, such as So the price maybe double or more than their purchase price. If there is a foundry which can supply cone liners for you by foundry price with the same quality as OEM supply, why you do not have a try?

Qiming Casting can service to you and waiting for your try!

Download Brochure

Download Brochure Product List

Product List