Chrome Ceramic Blow Bars By Qiming Casting®

Welcome to the world of high-performance chrome ceramic blow bars by Qiming Casting! Our cutting-edge blow bars are designed to revolutionize your crushing process, ensuring superior productivity, exceptional durability, and remarkable cost savings. Whether you’re in the mining, aggregate, or construction industry, our chrome ceramic blow bars are engineered to deliver outstanding results.

Benefits

- Experience Unmatched Performance

- Exceptional Durability, Extended Lifespan

- Superior Versatility, Enhanced Productivity

- Unbeatable Value, Cost Savings

What are chrome ceramic blow bars?

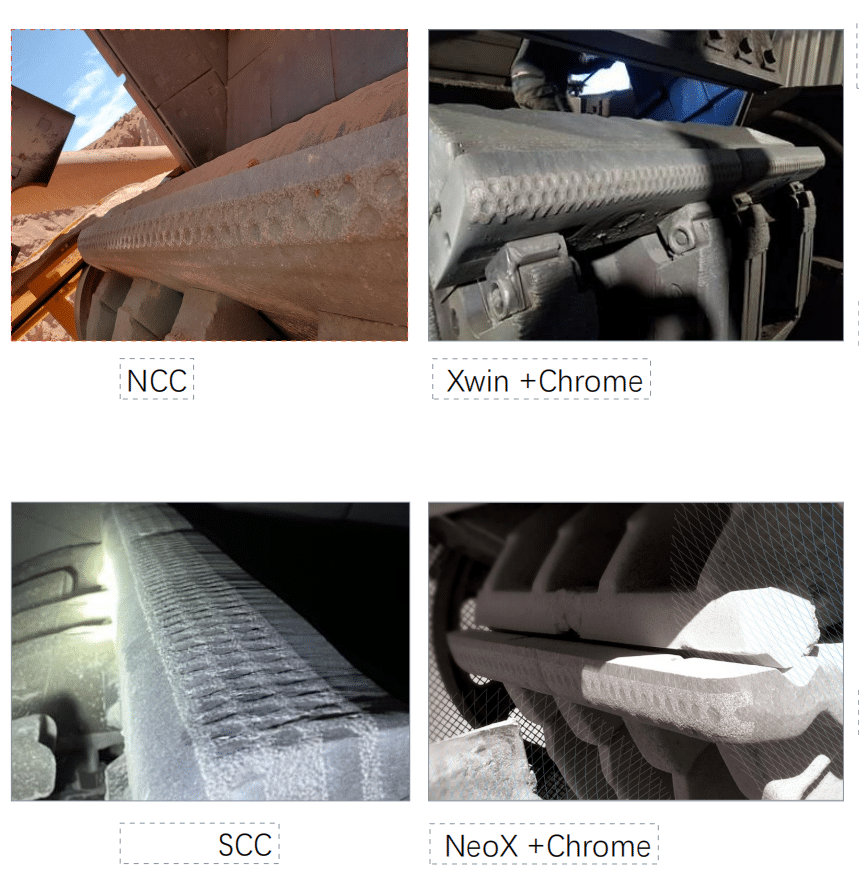

Chrome ceramic blow bars are advanced components used in crushing equipment, such as impact crushers, to enhance the efficiency and durability of the crushing process. These blow bars are engineered with a combination of high-chrome white iron and ceramic inserts, resulting in a unique composition that offers exceptional wear resistance and impact strength.

The high-chrome white iron provides excellent abrasion resistance, making the blow bars highly resistant to wear caused by the impact of hard materials. This durability ensures extended service life, reducing the need for frequent replacements and minimizing downtime.

The ceramic inserts embedded within the chrome matrix further enhance the performance of the blow bars. Ceramic materials, known for their exceptional hardness and toughness, provide additional resistance against wear and impact. They effectively dissipate heat generated during the crushing process, preventing premature wear and ensuring the blow bars maintain their structural integrity.

The combination of chrome and ceramic materials in these blow bars offers superior performance compared to traditional blow bars. They can withstand the most demanding crushing applications, whether it’s processing hard rock, concrete, or other challenging materials.

By utilizing chrome ceramic blow bars, crushing operations can achieve enhanced productivity, increased throughput, and reduced maintenance costs. These blow bars enable operators to crush materials more efficiently, resulting in improved overall operational efficiency and cost savings.

Overall, chrome ceramic blow bars are a game-changer in the crushing industry, providing exceptional durability, wear resistance, and impact strength. They offer significant advantages over conventional blow bars, ensuring longer service life, reduced downtime, and improved crushing performance.

Download Brochure

Download Brochure Product List

Product List